Factories have long fought waste. Scraps pile, energy leaks, workers repeat the same task. In a place where every extra cut, every broken part, every misstep costs money – waste is poison.

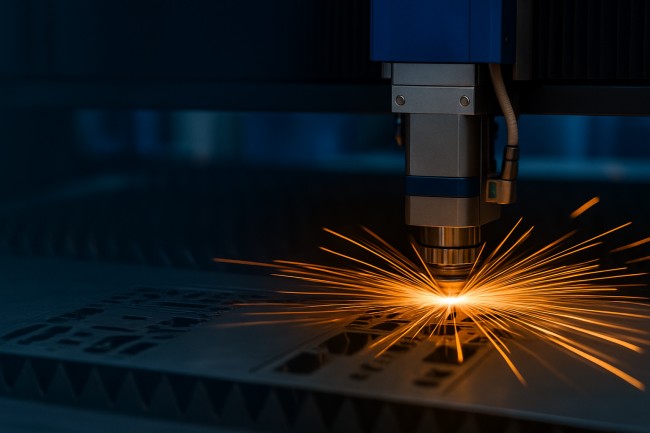

For years, fixes came slow. New machines. Faster conveyors. Cheaper materials. Then came lasers. Not the sci-fi beam that slices steel in films, though in truth, that’s not far off. These beams of light have slipped into factories and are rewriting the math of cost and waste.

Lasers are no longer fancy toys for labs. They cut, etch, weld, measure, and guide. And in doing so, they save factories piles of cash while shrinking the trash heap. Let’s dive deep into how.

The Shift From Blades to Beams

Factories used blades for ages. Sharp edges slicing steel, saws buzzing through wood, drills biting into plastics. The trouble? Blades dull. They wear down, chip, or warp. Every dull edge means imprecision. A crooked cut, wasted material, or a product tossed aside.

Lasers changed that equation. The beam cuts with heat, not friction. That means no tool wear, no frequent replacement, no downtime to swap parts. Production flows. Waste drops. Costs shrink.

But the story goes deeper. A laser beam is not just sharp. It is precise. In microns. A cut so exact you can nest shapes close, leaving little scrap. The material used to make ten parts before? Now enough for twelve. Over months, those margins matter.

Modern systems like a CNC laser push this even further. By blending computer control with laser precision, factories automate cutting paths, reduce operator error, and squeeze every inch of use from raw sheets.

Precision: The Silent Killer of Waste

Factories bleed money through tiny errors. A weld off by a hair. A hole drilled a fraction wide. A pattern etched slightly skewed. That tiny flaw means a whole unit scrapped. Or worse, shipped and returned later.

Lasers are ruthless against error. Controlled by software, guided by sensors, the beam repeats perfectly. Whether it’s the first part of the day or the thousandth, the cut looks the same. No wander, no chatter, no fatigue.

The beauty? Factories can reduce the “safety margin.” In the old days, engineers added extra material to guard against errors. Now, with lasers, the margin shrinks. Less buffer. Less waste.

Lasers in Welding: Fewer Defects, Stronger Joints

Traditional welding is messy. Sparks fly, filler rods melt, slag needs cleaning. Variations creep in – too hot, too fast, too slow. Defects hide in seams, waiting to crack. Each defect means rework, or worse, warranty claims.

Laser welding flips the script. The beam is focused, controlled, narrow. It penetrates just enough, making joints cleaner, tighter, stronger. Less distortion. Less post-process grinding. In industries like automotive or aerospace, that means fewer rejects and safer products.

Cost? Lower too. No constant filler rods. Less shielding gas. Reduced labor hours. Waste doesn’t pile up in bins, because there isn’t much waste to start with.

Cutting with Light: Leaner Sheets, Slimmer Costs

Walk through a sheet-metal factory. You’ll hear shears clanging, plasma cutters hissing, sparks raining down. Old methods chew through metal with force, leaving rough edges and plenty of offcuts.

A laser cutter glides. It makes clean cuts, smooth edges, little burr. Sheets can be arranged tight in software, minimizing leftover bits. The design nests like puzzle pieces. Material use climbs, scrap falls.

Machines such as the CNC laser excel here. The computer plots the puzzle, the laser executes it, and the factory reaps slimmer scrap piles.

Factories once threw away bins of jagged shards. With lasers, much less. And the scrap that remains? Easier to recycle because it’s clean, not contaminated by oils or tool debris. That reduces disposal costs. A double saving.

Marking and Engraving Without Waste

Product codes, logos, serial numbers – they need to be permanent. In the past, stamps dented metal, inks faded, or chemicals etched. All carried waste: spent ink, used acids, broken stamps.

Laser marking is different. The beam alters the surface without touching it. No consumables. No chemicals to store or discard. Once the laser etches, the mark lasts for life. Factories cut supply purchases, avoid toxic waste, and get marks that meet regulation without rework.

A small thing, yes. But in lean factories, even small waste matters.

Measurement with Lasers: Less Guesswork, More Yield

Waste isn’t only in cutting. Sometimes it hides in inspection. If a product passes faulty checks, it costs later in recalls. If the check is too strict, good parts get binned. Either way, money bleeds.

Laser measurement systems step in. They scan fast, in-line, non-contact. They read dimensions to fractions of a millimeter while parts move. That means no stoppage, no fixtures, no destructive testing. And the results are consistent, not dependent on tired human eyes.

More good parts pass, bad ones get flagged early. Less waste, higher yield.

Energy Use: Not All Waste Is Material

Factories don’t just waste steel, plastic, or wood. They waste energy. Motors humming idle. Furnaces running hot. Blades grinding longer than needed.

Lasers can cut energy bills. How? Precision again. A laser beam focuses power only where needed. It’s on, then off, instantly. No long warm-up, no wasted motion. Compared with older welding torches or furnaces, the difference is stark.

Energy waste is cost waste. And in a world pushing green manufacturing, this matters for compliance and for brand image.

Repair Instead of Replace

In the past, a defective part often meant scrap. Weld too wide? Toss it. Crack in a mold? Replace it. But lasers let factories repair.

Laser cladding, for instance, can deposit material back onto a worn part. A turbine blade with edge erosion can be rebuilt, not binned. A mold surface can be restored smooth. That means fewer replacements, lower raw material use, and less landfill.

The repair culture, powered by lasers, turns waste into value.

How Lasers Fit Lean Manufacturing

Lean manufacturing thrives on eliminating waste: time, motion, inventory, defects, over-processing. Lasers touch all these.

- Time: Faster setup, no tool change.

- Motion: One beam replaces multiple tools.

- Inventory: No stock of dies, stamps, or consumables.

- Defects: Precision cuts them down.

- Over-processing: Clean edges skip polishing steps.

A CNC laser fits neatly into this vision, cutting waste in both material and workflow.

Costs Behind the Curtain

Some managers balk at lasers. The machines aren’t cheap. A good industrial laser can cost six figures. That sticker shocks.

But cost must be weighed against savings. Less scrap metal. Lower labor hours. Fewer consumables. Reduced downtime. Energy cuts. Fewer returns. Over a few years, the math leans clear. The laser pays for itself and keeps giving.

Add another angle: safety. Lasers reduce moving parts, hot slag, sharp shards. Fewer accidents mean lower insurance, fewer sick days, higher morale. Not all savings show up on balance sheets, but they’re real.

The Role of Software and Automation

A laser alone is powerful. Linked to modern software, it’s a force. Computer-aided design meets computer-controlled beams. Machines nest patterns for minimum waste. Algorithms adjust power for each material thickness. Sensors feed back real-time data.

Automation takes it further. Robotic arms hold parts, rotate them, bring them under beams. Lasers work 24/7, without fatigue. Waste through error, mishandling, or stoppage drops. Costs follow.

Industries Leading the Charge

- Automotive: Lasers weld car bodies, cut panels, etch VINs. Every gram saved adds up in huge production volumes.

- Electronics: Tiny circuits need precision cutting and marking. One slip would ruin costly boards. Lasers prevent that.

- Aerospace: Materials here are pricey – titanium, composites. Waste is brutal. Lasers cut lean, weld light, inspect fast.

- Medical Devices: Need sterile, exact, permanent marks and cuts. Lasers deliver without chemicals.

Each of these industries faced high waste before. Lasers are changing their waste ledger line by line.

The Environmental Angle

Beyond money, there’s the planet. Waste dumped is not just cost, it’s pollution. Lasers shrink that. No oils, fewer chemicals, less scrap. Parts last longer, repairs extend life.

Factories lean on lasers not just to save costs but to meet strict green laws. Customers too look for eco-friendly supply chains. In that race, lasers are a silent ally.

Future Paths: Smarter, Smaller, Stronger

Lasers today are good. But tomorrow’s? Even better. Fiber lasers are efficient, compact, long-lived. Ultrafast lasers can cut without heat damage, opening doors to fragile materials. Integration with AI could adjust settings on the fly, spotting waste before it forms.

Factories won’t just use lasers to cut waste. They’ll predict it, prevent it, and perhaps eliminate it.

Final Thoughts

Factories live on thin margins. Waste tips the balance. For decades, managers chipped at the problem with small fixes. But lasers stepped in with a sharper answer – literally.

They cut, weld, mark, and measure with a precision no blade can match. They reduce scraps, slash energy use, extend tool life, and even repair the broken.

The upfront cost may sting. But the long game? It’s clear. Less waste. Lower costs. Greener footprints.

Lasers are not just beams of light. They are beams of change. And in the world of factories, change means survival.

Also Read: