Walk into any large facility, and the pattern repeats. Tools misplaced. Equipment records outdated. Stock counts that never align with reality. What starts as mild inconvenience soon becomes operational waste. That silent leakage is what Timly Software was built to stop.

From construction yards to hospitals, this Swiss-engineered platform gives every asset a digital identity. Laptops, forklifts, defibrillators, even screwdrivers – everything becomes traceable. Timly’s strength lies in turning what used to be invisible into structured, searchable data.

The Principle Behind Timly

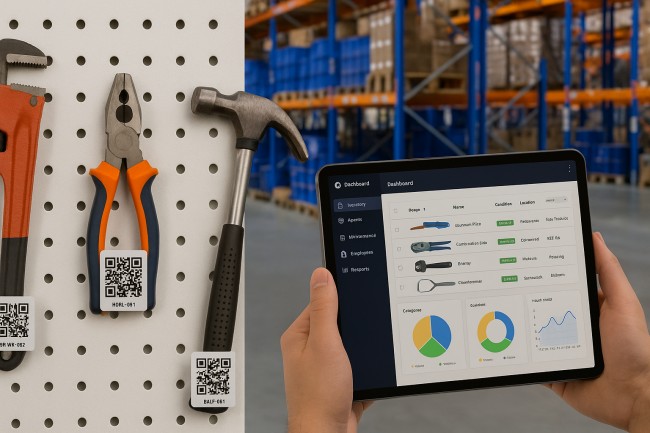

Timly runs on a simple promise: every asset should be knowable at any moment. It does that through digital tagging and centralized management. Each item receives a QR code or barcode; one scan connects the physical world with its digital twin.

That record carries all details – location, owner, condition, purchase data, and documentation. The information lives in a secure cloud interface, accessible from any device. Instead of emailing spreadsheets or chasing signatures, teams rely on one synchronized platform.

For distributed organizations juggling hundreds of moving pieces, that visibility changes everything. Misplaced equipment stops being a mystery and becomes traceable data.

Streamlined Equipment Tracking

Traditional asset tracking depends on memory and paperwork. Timly changes that dynamic through instant transparency.

Scan a QR code on a machine, and its entire lifecycle unfolds: purchase date, maintenance schedule, usage hours, and even photographs. Movement between sites updates automatically.

The interface color-codes items by status – available, in use, under maintenance, or retired. Managers can glance at the dashboard and understand operational readiness in seconds.

Such precision cuts losses, shortens audits, and replaces routine chaos with accountability. Equipment management becomes a measurable process, not a guessing exercise.

The Role of Maintenance Management

Every machine eventually breaks; the question is when and how prepared the team is. Timly’s maintenance scheduler answers that.

It allows users to set service intervals—either by time or usage metrics. When a date approaches, the system issues alerts. Technicians log repairs directly into the record, including cost, duration, and parts used.

Over time, those logs reveal trends. Which models fail too often? Which departments maintain assets better? Instead of anecdotal assumptions, managers rely on real data.

This approach doesn’t just keep machines healthy – it keeps compliance airtight. Safety inspections, calibration checks, and warranty renewals are automatically documented.

Inventory Management Re-Imagined

Inventory oversight tends to crumble when organizations scale. Timly prevents that slide by unifying consumable and fixed asset tracking.

Consumables – filters, cables, spare parts – are monitored with live stock levels. Minimum thresholds trigger restock alerts before shortages disrupt projects. Items can be assigned to departments or job sites, ensuring consumption is traceable.

Procurement teams gain instant visibility into stock flow. Instead of buying redundantly, they optimize usage. This equilibrium between control and flexibility defines Timly’s charm – it organizes without suffocating.

Real-Time Awareness Through IoT Integration

For companies managing vehicles or high-value machinery, static data isn’t enough. Timly extends its reach by linking with IoT sensors and GPS trackers.

Assets communicate their status continuously – location, vibration, temperature, or runtime. When anomalies appear, automated alerts flag potential faults before they become failures.

It’s predictive maintenance in action. The system listens to equipment and translates noise into intelligence. The result: downtime drops, and asset lifespans stretch further.

Mobile Functionality for On-Site Teams

Field operations thrive on movement, not paperwork. Timly’s mobile-first design fits naturally into that rhythm.

Technicians scan equipment with their smartphones, report damage, upload photos, or mark completion of maintenance – all within minutes. Data syncs instantly with the central database, keeping everyone aligned.

For industries like construction or logistics, this handheld simplicity eliminates hours of back-office reconciliation. The phone becomes both scanner and logbook.

Document Control and Security

Behind every tool lies documentation – certificates, manuals, insurance papers, safety approvals. Timly attaches them directly to asset records. No need to dig through folders or shared drives.

Access is governed by role-based permissions. Supervisors view everything, while operators see only relevant equipment. Audit trails record every action, ensuring traceability even during internal reviews.

The platform encrypts data at rest and in transit, maintaining confidentiality for organizations handling sensitive compliance material.

Integration with Existing Systems

Few platforms exist in isolation. Timly connects through REST APIs, exchanging data with ERP, accounting, or facility-management systems.

Procurement details, depreciation values, and cost allocations synchronize automatically. This prevents the twin nightmares of duplication and outdated entries.

That interoperability makes Timly adaptable – equally comfortable inside a small workshop or a multinational infrastructure.

Reporting That Informs, Not Overwhelms

Numbers matter only when they tell a story. Timly’s reporting tools present clear, concise insight.

Visual summaries show asset distribution, maintenance frequency, and cost curves. Exportable reports highlight bottlenecks or upcoming renewal deadlines.

Managers gain answers instead of clutter. Which site spends most on repairs? Which category shows under-utilization? The system lays it out without requiring a data scientist to interpret it.

Pricing and Implementation

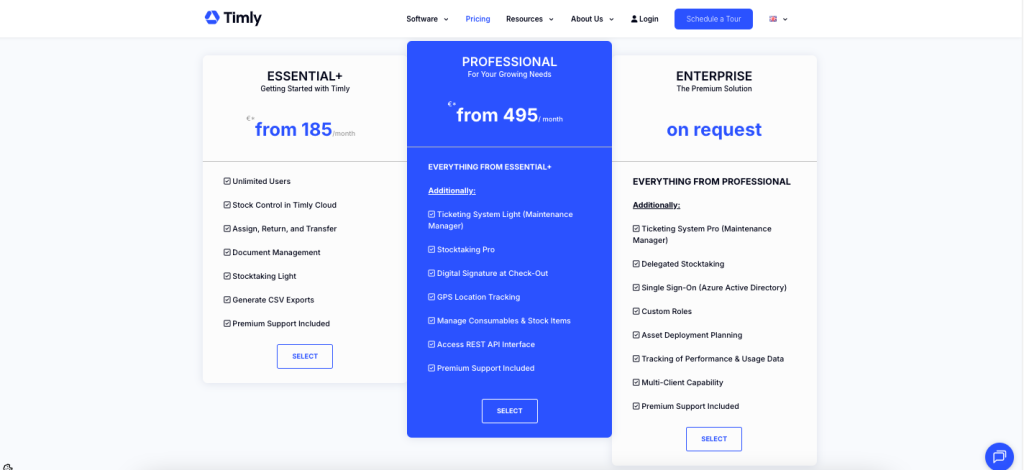

Timly operates on a subscription basis, with pricing starting near €185 per month, scaling according to asset volume and feature selection.

Implementation is straightforward. Data import tools allow migration from spreadsheets, and QR labels can be printed directly. Training requirements are minimal; the interface speaks plain logic.

For businesses used to clunky enterprise software, Timly’s learning curve feels refreshingly short.

Key Advantages of Using Timly

Timly’s greatest strength lies not in grand complexity but in quiet precision. Every module behaves as part of a single rhythm – clean, dependable, and surprisingly human.

- Unified Control: Instead of scattering tools, documents, and maintenance logs across multiple systems, Timly binds everything into one living environment. From the smallest screwdriver to the largest crane, every asset breathes within one interface.

- Mobility and Flexibility: The mobile app turns field technicians into data contributors. A quick QR scan updates status, records damage, or assigns equipment. That immediacy transforms responsibility into habit.

- Automation and Alerts: Maintenance reminders, calibration warnings, and inventory thresholds run in the background—no one needs to remember what the system never forgets.

- Transparency and Traceability: Every change, every scan, every edit leaves a digital footprint. It’s a transparent logbook that builds trust internally and credibility externally during audits.

- Scalability for Growth: Timly fits a 20-person workshop as comfortably as a global manufacturer. Databases expand fluidly, without the need for reconfiguration or migration headaches.

- Regulatory Assurance: Compliance becomes built-in rather than reactive. Certificates, safety records, and inspection results remain attached to assets—ready for any auditor, any time.

- Cost Visibility: By revealing utilization rates and repair patterns, Timly quietly uncovers areas where budgets leak. The insight helps leadership redirect funds toward efficiency instead of replacement.

Its biggest strength isn’t just technology – it’s discipline. Processes that once depended on memory now depend on system logic.

Areas Where It Could Grow

Perfection in software is a moving target, and Timly’s evolution still has road ahead. The gaps are not flaws; they’re opportunities waiting for refinement.

- Offline access: Limited capability in regions with unstable connectivity.

- Analytics depth: Complex trend visualization may require export to BI tools.

- Large-scale pricing: Costs rise with enterprise expansion.

These aren’t deal breakers, but practical realities. Timly prefers reliability over showmanship.

Who Benefits Most

Timly doesn’t belong to a single industry – it belongs to every operation haunted by disorganization. Yet certain sectors gain exceptional value:

- Construction & Engineering: Job sites scattered across cities depend on visibility. Timly ensures that heavy machinery, tools, and safety gear remain accounted for, reducing downtime and loss. Site managers can track movement, assign assets, and ensure that each tool is serviced before use.

- Healthcare & Laboratories: Precision and hygiene demand accountability. Hospitals use Timly to track sterilization logs, calibration schedules, and equipment certificates. It transforms regulatory compliance from a reactive scramble into a routine click.

- Manufacturing & Production Lines: Machines under constant stress need rhythm. Timly’s maintenance planner keeps them in tune, reducing unplanned stoppages and extending machine life. Plant managers finally view maintenance as data, not intuition.

- Municipalities & Public Infrastructure: Local governments manage fleets, waste systems, and road equipment. Timly helps departments track vehicles, record service intervals, and store compliance documents securely. Public accountability meets digital structure.

- IT & Facility Management: Laptops, routers, and office furnishings move frequently. Timly brings structure to that motion – tracking allocations, warranties, and replacements. It transforms IT inventory into an organized, auditable ecosystem.

- Education & Research Institutions: Schools and universities often misplace expensive lab gear and audiovisual tools. Timly’s QR-based tracking ensures visibility even across multiple campuses.

The unifying theme is discipline through visibility. Wherever assets matter, Timly converts uncertainty into certainty and chaos into continuity.

Conclusion

There’s a quiet brilliance in Timly’s approach. It doesn’t shout innovation through buzzwords – it delivers calm control through structure. By connecting every piece of equipment to its digital identity, it dissolves the distance between people, process, and product.

The transformation it brings isn’t abstract. It’s visible in reduced downtime, fewer losses, and cleaner records. What once hid in drawers or memory now lives openly in data.

In the age of automation, Timly Software offers something simple yet profound – order. A kind of order that turns inventory tracking from daily frustration into quiet confidence.

Also Read: